Here I will compile the products of my researches on single transistor FM radio receiver.

Generally when we think about FM radio receiver, what will be first to usually pop into our mind will be a complex kind of radio receiver, more than a diode and coil as usually utilised in AM radio receiver. In actuality its not the case when we take into consideration the original FM radio receiver invented by the FM radio transmitting pioneer Edwin Armstrong. He was credited with the invention of the first practical FM radio receiver, which use ONLY one non-linear electronic component ( the vacuum tube).

source:http://en.wikipedia.org/wiki/File:Regenerative_Receiver.png

The first FM radio receiver, using vacuum tube in regenerative topology.

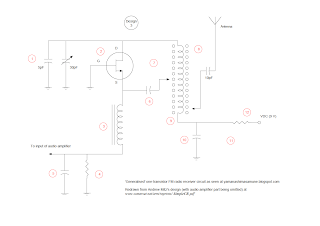

With the invention of junction field-effect transistor, the vacuum tube was subsequently omitted from the circuit and being substituted by JFET. From my analysis on various FM receiver circuits found on internet I concluded a final generalised version of single transistor FM regenerative receiver as shown below:

FM radio receiver using just one JFET transistor as an active non linear element, in regenerative topology.

Most of single transistor FM radio receiver circuits I found on the internet dont deviate much from the above generalised design,except few which are completely different from it. But like I said, most of it follow the above configuration.

Now I am going to explain each part of the circuit, each numbered point below refers to corresponding red circled number in the diagram:

1) Group of capacitors: Some of the designs use capacitors arranged only parallely, while others just in series. Some omit the variable capacitors. So this part depends on the designer's choice. The value of the capacitors much be carefully chosen cuz it will determine the bandwidth within where the circuit will resonate. For FM receiver, the corresponding resonant frequency must be within 80 to 108 MHz.

2) The JFET transistor: From analysis I found out collections of transistor types suitable for the operation. Here are the examples: MPF102 (frequently used), BF245, J310 ( is now obsolete), 2N4416, RS2003 (Radio Shack JFET), 2N3819, BF256.

3) RF choke: The purpose of RF choke is to block high frequency signal from reaching the audio amplifier. It can be home-made, by just winding copper wire around a cylindrical air core or ferrite torroid. Various kinds of choke are made depending on the designers' choices.

4) Resistor: The value of the resistor can be adjusted to obtain the most clear audio output.

5) Capacitor: Same with resistor at (4)

6)Feedback capacitor: Its value is also designer's choice. This capacitor taps the coil at (7) to form a regenerative topology.

7) Capacitor's tap points: Part of the coil where the feedback capacitor touches. The position where the feedback capacitor taps is designer's choice.

8) Antenna and antenna's tap points: antenna touches the coil at the antenna's tap points. The length of the antenna, and the position of tap are the designer's choices.

9) Coil: the number of turns, the length and the diameter are all designer's choices.

10), 11) and 12) are capacitor and resistors to regulate the power supply. Their values are again, designers' choices.

By using this generalised circuit, anyone can play with various choice of values of any of the involved components, coils and transistors without being restricted to the designs proposed on the internet. It enables everyone to even create their own variants of FM single transistor receiver. To be honest, I ve tried various FM single transistor designs but none of them worked. And I m still trying hoping one day I will found a working one and this general design helps me alot in constructing various new variants.

Below I will show u several circuit designs made by several hobbyists, which I redrawn and omitted the audio amplifier part to enable easy matching with the general circuit proposed before.

Design 1: Philip Crane's design

Design choices (all numbered points refer to corresponding circled red numbers on the diagram):

2) JFET transistor: MPF102

3) RF choke: 26 turns, 30 AWG wire, 8mm diameter coil

4) resistor: 10kOhm

5) capacitor: 4.7nF

6) capacitor: 4.7-5pF

7) Tap: close to JFET's Drain

8) antenna's tap: 2 turns from power supply

9) coil: 22AWG wire 7 turns 2 inches long coil around 5/16" former

10) capacitor: 1nF

11) resistor: 1kOhm

12) 9V power supply

Design 2: Andrew Mitz's design

Design choices (all numbered points refer to corresponding circled red numbers on the diagram):

2) JFET transistor: 2N4416

3) RF choke: 22uHenry choke

4) resistor: 10kOhm

5) capacitor: 5nF

6) capacitor: 24pF

7) Tap: centre tap, soldered

8) antenna's tap: no antenna

9) coil: gauge unknown (assume 18AWG), 6 turns around 0.5inches diamter former, length 0.75 inches

10) capacitor: 1nF

11) resistor: 1kOhm

12) 9V power supply

Design 3: Andrew Mitz's design

Design choices (all numbered points refer to corresponding circled red numbers on the diagram):

2) JFET transistor: 2N4416

3) RF choke: 100uHenry choke

4) resistor: none

5) capacitor: 5nF

6) capacitor: 24pF

7) Tap: centre tap, soldered

8) antenna's tap: 3/4 of a turn from 10nF capacitor, antenna has 10pF capacitor on it as shown

9) coil: 18AWG wire, 12 turns around 3/8 inches diamter former, close winding (close wrap)

10) capacitor: 10nF

11) resistor: 1kOhm

12) 9V power supply

Design 4: Patrick Cambre's design

Design choices (all numbered points refer to corresponding circled red numbers on the diagram):

2) JFET transistor: MPF102

3) RF choke: 20 wraps of 24AWG around 5/16 inches former

4) resistor: 10kOhm

5) capacitor: 4.7nF

6) capacitor: each 5.6pF

7) Tap: tap closest to Drain of JFET

8) antenna's tap: Tap closest to power supply

9) coil: 22AWG wire, 8-10 turns around 5/6 inches diamter former

10)1nF capacitor 11) and 12) as shown

Design 5: Alan Yates's design

Design choices (all numbered points refer to corresponding circled red numbers on the diagram):

2) JFET transistor: J310 or MPF102

3) RF choke: 25uHenry choke

4) resistor: 10kOhm

5) capacitor: 6.8nF

6) capacitor: 10pF

7) Tap: centre tap

8) antenna's tap: no antenna

9) coil: 5 turns 7mm diameter and length (inductance about 120nHenries)

10) capacitor: 1nF

11) resistor: none

12) 9V power supply

Design 6: mikroElektronika's design

Design choices (all numbered points refer to corresponding circled red numbers on the diagram):

2) JFET transistor: BF256

3) RF choke: 22uHenry choke

4) resistor: 10kOhm to 22kOhm

5) capacitor: 6-100nF

6) capacitor: 22pF

7) Tap: centre tap, soldered

8) antenna's tap: closest to the Drain of JFET

9) coil: 5 turns 0f 0.9mm diameter wire (close wrap) 9mm diameter coil

10) capacitor: 1nF

11) resistor: 1kOhm

12) 9V power supply

Thats all from me. Hope this will help.

The world is not run by mere theorists. It is run by the ones who convince and prove to the world that thing's gonna work.

Friday, 28 October 2011

Friday, 7 October 2011

Cockroft-Walton voltage multiplier.

Cockroft-Walton voltage multiplier (CW multiplier) is another type of voltage multiplier that is widely used apart from Marx generator discussed before. It was initially used by scientists John Cockroft and Ernest Walton to perform atom splitting experiment, which earned them the Nobel Prize in Physics in 1951.

I built a simple battery-powered CW multiplier just to get 2mm spark, which enough to lit up a match or a cigarette lighter. As I ve explained long ago, the output from the 555 inverter must be amplified using LM386 before sending to the transformer to get such spark, but what if I didnt have LM386 but instead bunches of diodes and capacitors in my possession? Those diodes and capacitors are enough to substitute the role of LM386, by 'amplifying' the voltage as a CW voltage multiplier.

The function of CW multiplier is very simple. The fed alternating current from the transformer's output will go into the input of the CW multiplier. On first half of the cycle (first half wave), it will charge the first capacitor through the first diode. On second half wave, it will discharge the first capacitor thru the second capacitor and the second diode, so now the voltage stored at the second capacitor will be twice the first voltage stored at the first capacitor. By the end of the whole cycle, second capacitor holds twice the voltage of the supply while the first capacitor holds nothing. This operation is the first stage of the entire operation. Since I have 13 diodes-capacitors pairs, therefore I used about 6 and a half stages of multiplying.

But why the spark is so small ie 2mm length?? That is becuz the voltage generated from the transformer is very low. I measured it was about 180 to 200 V only, comparable to its original inverted operation which is to step down the mains voltage (240V) to about 2-3V ( the transformer is salvaged from battery charger, which was the one i ve been using before). By using CW multiplier, I got 2mm spark which was about 600 V. Though there are about six stages of multiplying I couldnt get six time the voltage from transformer due to diodes internal resistances. Anyway, this is worth experimenting so u know how much u will get by CW-multiplying voltage from a single 9V battery, using just a common battery charger transformer and a 555 inverter.

Below is the circuit I ve used:

Below are the photos taken:

The overall circuit.

The CW multiplier part. Note the white glue tape roller. It was made a former of the spark gap, where the 2mm spark will be observed.

Mains step down transformer salvaged from battery charger

The inverter part. I ve used the 555 inverter circuit.

I built a simple battery-powered CW multiplier just to get 2mm spark, which enough to lit up a match or a cigarette lighter. As I ve explained long ago, the output from the 555 inverter must be amplified using LM386 before sending to the transformer to get such spark, but what if I didnt have LM386 but instead bunches of diodes and capacitors in my possession? Those diodes and capacitors are enough to substitute the role of LM386, by 'amplifying' the voltage as a CW voltage multiplier.

The function of CW multiplier is very simple. The fed alternating current from the transformer's output will go into the input of the CW multiplier. On first half of the cycle (first half wave), it will charge the first capacitor through the first diode. On second half wave, it will discharge the first capacitor thru the second capacitor and the second diode, so now the voltage stored at the second capacitor will be twice the first voltage stored at the first capacitor. By the end of the whole cycle, second capacitor holds twice the voltage of the supply while the first capacitor holds nothing. This operation is the first stage of the entire operation. Since I have 13 diodes-capacitors pairs, therefore I used about 6 and a half stages of multiplying.

But why the spark is so small ie 2mm length?? That is becuz the voltage generated from the transformer is very low. I measured it was about 180 to 200 V only, comparable to its original inverted operation which is to step down the mains voltage (240V) to about 2-3V ( the transformer is salvaged from battery charger, which was the one i ve been using before). By using CW multiplier, I got 2mm spark which was about 600 V. Though there are about six stages of multiplying I couldnt get six time the voltage from transformer due to diodes internal resistances. Anyway, this is worth experimenting so u know how much u will get by CW-multiplying voltage from a single 9V battery, using just a common battery charger transformer and a 555 inverter.

Below is the circuit I ve used:

Below are the photos taken:

The overall circuit.

The CW multiplier part. Note the white glue tape roller. It was made a former of the spark gap, where the 2mm spark will be observed.

Mains step down transformer salvaged from battery charger

The inverter part. I ve used the 555 inverter circuit.

Friday, 23 September 2011

Single-transistor flyback drivers.

keywords: single transistor flyback driver, single MOSFET flyback driver, simple flyback driver, one transistor flyback driver.

So far, i have dealt with several powerful flyback drivers such as ZVS and 555 timer. To be honest i m more interested in a simpler but powerful flyback driver, so i researched about drivers that utilise only one transistor.

The most popular one-transistor flyback driver is one that uses the ubiquitous 2N3055 NPN silicon power transistor. The schematic is as shown below. The number of turns of the primary is not critical but generally the trickler coil ( the one connected to the Base of the transistor) is having lower number of turns than that connected to the transistor's Collector.

My own variant of the circuit. This topology is also known as Armstrong oscillator, due to Edwin Armstrong who invented and applied this topology for his regenerative FM radio receiver. To recognise this topology is very easy; it has two coils, one having more turns than the other, and it has only one transistor ( or traditionally, a vacuum tube).

Surprisingly, when I substituted the transistor with MOSFET, the circuit is still working. I substituted the Collector, Base and Emitter of the transistor with the Drain, Gate and Source of the MOSFET, respectively. IRF840 and IRFP250N worked successfully, but it didnt work with IRFP450 ( dont know why, if u know why then u can teach me in the comment section). Below is the same circuit, but using MOSFET as an active component.

For both circuits, I found out that my laptop power supply that I m always been using ( 12 V, 3.16 A) cannot be used anymore for these circuits, since it baked the transistors and MOSFETs and if not, degraded them significantly, even though i ve used zener diodes at the base or gate of the devices. I inferred that might be due to large current (3.16 A) of the supply. Therefore I resorted to simpler supply which is the common 9V square battery. Both circuits produced less powerful arc than ZVS or 555 driver ( maybe due to lower power when using battery), and the arc was about 0.5 to 1 cm length. The winding direction of the trickler coils of both circuits can be reversed, and it still works successfully. I know that the circuit can be further improved so that it can fit larger power supply, but my superficial electronic knowledge and tight budget ( i am poor student, T_T) limit improvements and haunt me of more transistor burnings (so far I ve burnt between ten to twenty MOSFETs during three months of experimenting, and each of them worth 1pound. So count by yourself how much lost i ve been facing!). I really hope someone can tell me how the circuits above can be improved for larger power supply. :D

Below is the circuit that didnt work EVEN when using the battery power supply ( I think this circuit actually didnt work, it just damages your MOSFETs and BJT). I just posted it here cuz I am perplexed with most designs of Armstrong oscillator that utilises the following configuration. I dont know the reason behind that, but it seems that most of the designs are using higher power supply. (such as 50, 100 to 140 W, while the highest power supply i have which is the laptop power suppy is just 40 W, in fact, always lower than that!) I also hope that someone experts can explain why the following circuit didnt work.

This circuit doesnt work even when using 2N3055 transistor.

So far, i have dealt with several powerful flyback drivers such as ZVS and 555 timer. To be honest i m more interested in a simpler but powerful flyback driver, so i researched about drivers that utilise only one transistor.

The most popular one-transistor flyback driver is one that uses the ubiquitous 2N3055 NPN silicon power transistor. The schematic is as shown below. The number of turns of the primary is not critical but generally the trickler coil ( the one connected to the Base of the transistor) is having lower number of turns than that connected to the transistor's Collector.

My own variant of the circuit. This topology is also known as Armstrong oscillator, due to Edwin Armstrong who invented and applied this topology for his regenerative FM radio receiver. To recognise this topology is very easy; it has two coils, one having more turns than the other, and it has only one transistor ( or traditionally, a vacuum tube).

Surprisingly, when I substituted the transistor with MOSFET, the circuit is still working. I substituted the Collector, Base and Emitter of the transistor with the Drain, Gate and Source of the MOSFET, respectively. IRF840 and IRFP250N worked successfully, but it didnt work with IRFP450 ( dont know why, if u know why then u can teach me in the comment section). Below is the same circuit, but using MOSFET as an active component.

For both circuits, I found out that my laptop power supply that I m always been using ( 12 V, 3.16 A) cannot be used anymore for these circuits, since it baked the transistors and MOSFETs and if not, degraded them significantly, even though i ve used zener diodes at the base or gate of the devices. I inferred that might be due to large current (3.16 A) of the supply. Therefore I resorted to simpler supply which is the common 9V square battery. Both circuits produced less powerful arc than ZVS or 555 driver ( maybe due to lower power when using battery), and the arc was about 0.5 to 1 cm length. The winding direction of the trickler coils of both circuits can be reversed, and it still works successfully. I know that the circuit can be further improved so that it can fit larger power supply, but my superficial electronic knowledge and tight budget ( i am poor student, T_T) limit improvements and haunt me of more transistor burnings (so far I ve burnt between ten to twenty MOSFETs during three months of experimenting, and each of them worth 1pound. So count by yourself how much lost i ve been facing!). I really hope someone can tell me how the circuits above can be improved for larger power supply. :D

Below is the circuit that didnt work EVEN when using the battery power supply ( I think this circuit actually didnt work, it just damages your MOSFETs and BJT). I just posted it here cuz I am perplexed with most designs of Armstrong oscillator that utilises the following configuration. I dont know the reason behind that, but it seems that most of the designs are using higher power supply. (such as 50, 100 to 140 W, while the highest power supply i have which is the laptop power suppy is just 40 W, in fact, always lower than that!) I also hope that someone experts can explain why the following circuit didnt work.

This circuit doesnt work even when using 2N3055 transistor.

Wednesday, 14 September 2011

Marx generator.

Marx generator is a voltage multiplier that multiply the high voltage direct current to a higher voltage level, by charging a group of capacitors in parallel, and discharging them in series.

I built a Marx generator with original intention to increase input power into my Tesla coil, but didnt working. However its still working as a Marx generator itself, so still worth mentioning in this blog. :P

The operation of Marx generator can be best understood by studying the diagram, retrieved from Wikipedia:

My version of Marx generator has no major difference from any other versions. i used three-stage multiplying, using three 2-litre bottle saltwater capacitors wrapped in aluminium foil as plates. Each of the capacitors was measured to be 5nF in capacitance. There are three spark gaps, where two are small spark gaps as switches and a final spark gap. I ve made the final spark gap larger than the other two, and connecting it directly to ground instead to a voltage divider and load ( as depicted in the above diagram).

For the spark gaps, I have two small spark gaps each of 1.5mm gap length ( it varies around that value cuz u need to synchronise it to get best length in order to avoid corona discharge, cuz corona discharge between the gap may spoil the operation). The spark gap was made by screwing two metal screw into a circular former, either by using glue tape roller, or plastic bottle caps. I used screw to enable easy synchronisation of the gap length during operation.

All the resistors are at 1 megOhm each. The final(big) spark gap was also constructed similar to other two spark gaps. Initially i set the final spark gap length to be 0.5cm, and increased it gradually to get the maximum spark length that can be obtained from the overall configuration of the Marx generator. The maximum spark length observed is about 1.5cm. Yes, its too short for most hobbyists, due to small number of stages ive been using. I am intending on buying more high voltage capacitors to reduce size ( saltwater capacitors are too big and heavy) and make the overall design compact and smaller ( and portable as well) as well as increasing the number of stages to maybe 20 to 30 stages. I wonder how long the spark i will get...

Here is the schematic of the marx generator built:

Here are the photos taken:

The overall setup. Ignore everything outside the A4 papers boundary. Just focus the interior. The noticeable three big bottles are my saltwater capacitors of 5nF capacitance each. I m using my ZVS power oscillator (but changed the 1N4007 diode to BYV26E, IRF840 transistor to IRFP250N, and 10nF capacitor to high voltage rating 1uF capacitor for faster switching, cooler mosfet and higher efficiency and power) fed the oscillating power into the flyback transformer. The transformer rectified the oscillating current in it so there is no need to use diode. The high voltage direct current is then fed into my Marx generator.

Closer view.

Power supply ( laptop power supply, 12V,3.16A as always used before) which is the black wire with yellow wire at its end, breadboard populated with components in ZVS oscillator confg, and a flyback transformer ( the only chunky thing close to the breadboard)

Capacitors and small spark gaps bird eye's view.

Closer look on the small spark gaps. The white one was not used, so i closed the gap.

The small spark gap using screws and plastic bottle cap.

Another small spark gap, also using screws and plastic bottle cap.

As mentioned before, this small spark gap is not used, so i closed the gap. This was constructed cuz i though another small spark gap would be necessary before the final big spark gap, but when finding out it wasnt important later on I just leave it there by closing it. This gap was constructed with glue tape former and two screws.

This is the final and the biggest spark gap where the final product of the Marx generator ( the longest spark) will be observed. It was constructed similar to the unused small spark gap. Just ignore the red tape former over it cuz it is just to hold the wires carrying voltage to the final spark gap in place.

Final (big) spark gap.

Here is the video. I have to put on a video this time cuz it was really hard to capture a photo of a flashing spark. Enjoy it!

I built a Marx generator with original intention to increase input power into my Tesla coil, but didnt working. However its still working as a Marx generator itself, so still worth mentioning in this blog. :P

The operation of Marx generator can be best understood by studying the diagram, retrieved from Wikipedia:

My version of Marx generator has no major difference from any other versions. i used three-stage multiplying, using three 2-litre bottle saltwater capacitors wrapped in aluminium foil as plates. Each of the capacitors was measured to be 5nF in capacitance. There are three spark gaps, where two are small spark gaps as switches and a final spark gap. I ve made the final spark gap larger than the other two, and connecting it directly to ground instead to a voltage divider and load ( as depicted in the above diagram).

For the spark gaps, I have two small spark gaps each of 1.5mm gap length ( it varies around that value cuz u need to synchronise it to get best length in order to avoid corona discharge, cuz corona discharge between the gap may spoil the operation). The spark gap was made by screwing two metal screw into a circular former, either by using glue tape roller, or plastic bottle caps. I used screw to enable easy synchronisation of the gap length during operation.

All the resistors are at 1 megOhm each. The final(big) spark gap was also constructed similar to other two spark gaps. Initially i set the final spark gap length to be 0.5cm, and increased it gradually to get the maximum spark length that can be obtained from the overall configuration of the Marx generator. The maximum spark length observed is about 1.5cm. Yes, its too short for most hobbyists, due to small number of stages ive been using. I am intending on buying more high voltage capacitors to reduce size ( saltwater capacitors are too big and heavy) and make the overall design compact and smaller ( and portable as well) as well as increasing the number of stages to maybe 20 to 30 stages. I wonder how long the spark i will get...

Here is the schematic of the marx generator built:

Here are the photos taken:

The overall setup. Ignore everything outside the A4 papers boundary. Just focus the interior. The noticeable three big bottles are my saltwater capacitors of 5nF capacitance each. I m using my ZVS power oscillator (but changed the 1N4007 diode to BYV26E, IRF840 transistor to IRFP250N, and 10nF capacitor to high voltage rating 1uF capacitor for faster switching, cooler mosfet and higher efficiency and power) fed the oscillating power into the flyback transformer. The transformer rectified the oscillating current in it so there is no need to use diode. The high voltage direct current is then fed into my Marx generator.

Closer view.

Power supply ( laptop power supply, 12V,3.16A as always used before) which is the black wire with yellow wire at its end, breadboard populated with components in ZVS oscillator confg, and a flyback transformer ( the only chunky thing close to the breadboard)

Capacitors and small spark gaps bird eye's view.

Closer look on the small spark gaps. The white one was not used, so i closed the gap.

The small spark gap using screws and plastic bottle cap.

Another small spark gap, also using screws and plastic bottle cap.

As mentioned before, this small spark gap is not used, so i closed the gap. This was constructed cuz i though another small spark gap would be necessary before the final big spark gap, but when finding out it wasnt important later on I just leave it there by closing it. This gap was constructed with glue tape former and two screws.

This is the final and the biggest spark gap where the final product of the Marx generator ( the longest spark) will be observed. It was constructed similar to the unused small spark gap. Just ignore the red tape former over it cuz it is just to hold the wires carrying voltage to the final spark gap in place.

Final (big) spark gap.

Here is the video. I have to put on a video this time cuz it was really hard to capture a photo of a flashing spark. Enjoy it!

Saturday, 13 August 2011

Tesla coil; resonance demonstration.

Today i ve nothing new project to post except to just wanna explain my recent demonstration of resonance and wireless energy transfer using mini Tesla coil i ve built recently.

Resonance is the very fundamental concept that enables the functions of most current ubiquitous wireless devices. Radio receiver, handset, radar,satellite and televisions are all dependent on this principle.

Resonance occurs when the frequency of the energy supplied to a system is the same as the natural frequency of the system. At resonance, the system will receive most energy from the energy source, and tend to damage itself, unless controlled.

In Tesla coil, like no other conventional transformers, the secondary coil resonates with the primary coil. Hence, most of the energy supplied by the primary coil will be intercepted by the secondary coil and this in turn increases efficiency. To achieve this, of course (by the definition of resonance) the natural frequency of the tank circuit formed by the capacitor and the primary must be the same with the tank circuit formed by the air-earth 'capacitor' and the secondary. Since the secondary coil tends to damage itself with excessive energy being transferred into it, therefore a spark gap is made at the primary coil to release the excess energy.

Since resonance occurs at the same frequency of energy source and receiving system, i wondered whether the energy received by the secondary coil can be transferred further to a similar system with same or almost same natural frequency. Due to this, i constructed a third coil , which is having same diameter, length, wire diameter in order to make its natural frequency as close as possible to that of the secondary coil. The following diagram shows the secondary coil and the third coil.

Both coils, secondary and third coils.

Current setup. Its the same i ve been using before. The 275ml bottle wrapped in aluminium foil is my homemade capacitor. I chose this one cuz it gives longest spark on the secondary ie it enables the primary ( the yellow wire) to resonate with the secondary.

The system, without the third coil. A strand of corona was pulled by using screwdriver. Its about 1.5cm length.

When putting the third coil in the vicinity of the secondary coil, it resonates and due to this, a 0.7cm can be observed between the screwdriver and the breakout point. How do i prove that it really resonates and not receiving energy from the yellow wire ( the primary coil)? I removed the secondary winding away, and then tried powering the circuit again. And no spark was observed at the third coil. This proves that it really resonates with the secondary coil.

How the resonance is applied in telecommunication? Well, i guess u can contemplate over the experiment. The secondary is the transmitter of the energy while the third coil is your 'handset', television, radio receiver and any type of wireless devices. The differences between resonance observed in my demonstration and the resonance in real application in wireless devices are that the power is transferred at larger distance and higher band of frequencies, and the power is not only bringing itself, it also brings signals ( it is modulated )that will be translated and amplified into perceivable video and audio signals.

Resonance is the very fundamental concept that enables the functions of most current ubiquitous wireless devices. Radio receiver, handset, radar,satellite and televisions are all dependent on this principle.

Resonance occurs when the frequency of the energy supplied to a system is the same as the natural frequency of the system. At resonance, the system will receive most energy from the energy source, and tend to damage itself, unless controlled.

In Tesla coil, like no other conventional transformers, the secondary coil resonates with the primary coil. Hence, most of the energy supplied by the primary coil will be intercepted by the secondary coil and this in turn increases efficiency. To achieve this, of course (by the definition of resonance) the natural frequency of the tank circuit formed by the capacitor and the primary must be the same with the tank circuit formed by the air-earth 'capacitor' and the secondary. Since the secondary coil tends to damage itself with excessive energy being transferred into it, therefore a spark gap is made at the primary coil to release the excess energy.

Since resonance occurs at the same frequency of energy source and receiving system, i wondered whether the energy received by the secondary coil can be transferred further to a similar system with same or almost same natural frequency. Due to this, i constructed a third coil , which is having same diameter, length, wire diameter in order to make its natural frequency as close as possible to that of the secondary coil. The following diagram shows the secondary coil and the third coil.

Both coils, secondary and third coils.

Current setup. Its the same i ve been using before. The 275ml bottle wrapped in aluminium foil is my homemade capacitor. I chose this one cuz it gives longest spark on the secondary ie it enables the primary ( the yellow wire) to resonate with the secondary.

The system, without the third coil. A strand of corona was pulled by using screwdriver. Its about 1.5cm length.

When putting the third coil in the vicinity of the secondary coil, it resonates and due to this, a 0.7cm can be observed between the screwdriver and the breakout point. How do i prove that it really resonates and not receiving energy from the yellow wire ( the primary coil)? I removed the secondary winding away, and then tried powering the circuit again. And no spark was observed at the third coil. This proves that it really resonates with the secondary coil.

How the resonance is applied in telecommunication? Well, i guess u can contemplate over the experiment. The secondary is the transmitter of the energy while the third coil is your 'handset', television, radio receiver and any type of wireless devices. The differences between resonance observed in my demonstration and the resonance in real application in wireless devices are that the power is transferred at larger distance and higher band of frequencies, and the power is not only bringing itself, it also brings signals ( it is modulated )that will be translated and amplified into perceivable video and audio signals.

Monday, 8 August 2011

Tesla coil; first attempt.

Tesla coil is a type of resonant transformer, where the voltage output from the secondary turn is not dependent on the turns ratio between primary and secondary turns, but dependent on the square root of the ratio between primary inductance and secondary inductance.

Here is my first attempt on building a mini Tesla coil. The secondary coil (where the sparks will be observed) is a 500-turn winding, wound around a kitchen naptkin's cardboard roll of 5cm outer diameter and of 20cm length. The primary coil is 8-turn winding, wound around a big glue tape roller of about 9cm outer diameter. I drive this coil using ZVS power oscillator (see schematic here) but using different type of capacitor (1uF, non polar). Like no other configuration of the ZVS, this new configuration of ZVS i ve been using rendered the MOSFETs very hot after 1 minute running time, forcing me to put heatsinks on each MOSFET.

Running on 12V, 3.16A power supply fed into the ZVS circuit. I am still researching on how to enlarge the spark and make them blue since the purple spark is not a spark, its a corona due to presence of water vapor around the carrying conductor.

I dont know why the camera suddenly perceived the spark as blue although it was purple.

In the dark.

I m using spark gap, so this tesla coil can be regarded as SGTC (spark gap tesla coil).

The capacitor i ve been using is a single homemade leyden jar, made from 275ml juice bottle, with brine in it and aluminium on the outer part as plates.

Here is the schematic of the tesla coil from the high voltage output. The diode is already in the flyback transformer that receives oscilated current from the ZVS circuit.

I m still improving the design to get larger spark and less hot transistors. See ya later.

Here is my first attempt on building a mini Tesla coil. The secondary coil (where the sparks will be observed) is a 500-turn winding, wound around a kitchen naptkin's cardboard roll of 5cm outer diameter and of 20cm length. The primary coil is 8-turn winding, wound around a big glue tape roller of about 9cm outer diameter. I drive this coil using ZVS power oscillator (see schematic here) but using different type of capacitor (1uF, non polar). Like no other configuration of the ZVS, this new configuration of ZVS i ve been using rendered the MOSFETs very hot after 1 minute running time, forcing me to put heatsinks on each MOSFET.

Running on 12V, 3.16A power supply fed into the ZVS circuit. I am still researching on how to enlarge the spark and make them blue since the purple spark is not a spark, its a corona due to presence of water vapor around the carrying conductor.

I dont know why the camera suddenly perceived the spark as blue although it was purple.

In the dark.

I m using spark gap, so this tesla coil can be regarded as SGTC (spark gap tesla coil).

The capacitor i ve been using is a single homemade leyden jar, made from 275ml juice bottle, with brine in it and aluminium on the outer part as plates.

Here is the schematic of the tesla coil from the high voltage output. The diode is already in the flyback transformer that receives oscilated current from the ZVS circuit.

I m still improving the design to get larger spark and less hot transistors. See ya later.

Thursday, 4 August 2011

Zero voltage switching (ZVS) technique.

Though the 555 driver i ve been using is quite good in running the flyback, however the MOSFETs were easily heated up . I ve broken about 3-4 MOSFET since i ve been using it. Therefore, when i was searching for a more robust flyback driver in order to use it as my tesla coil power supply afterwards, i realized that zero voltage switching (ZVS) flyback driver can give high voltage without heating the MOSFET too much ( sometimes even none!). Hence, i turned to ZVS from that instance.

The most popular ZVS flyback driver nowadays amongst hobbyists is that designed by Vladimiro Mazilli. This driver is called zero voltage switching driver cuz it switches current exactly when the voltage across the MOSFET equals zero, and give a pure sine wave output, hence behaving like an DC-AC converter or 'inverter'. Due to its ability to convert the input DC into sine wave rather than sawtooth signal (from 555 driver circuit), hence the noise or the transformer's hum can be reduced or sometimes, entirely eliminated at all.

I ve been testing the ZVS driver with all electronic components i ve got so far ( since i dont wanna buy too much to reduce cost, i m short of money right now), and yesterday i finally found the most optimal configuration or variant of the circuit, where no more mosfet, diode and zener diode are broken ( honestly, i ve broke several zener diodes, some mosfets and also common rectifier diodes in the process).

The spark generated from the transformer is quite solid and smooth, no hum from the transformer's core, and the mosfet and all of the components on the circuit are not even getting warm at all. The only disadvantage from ZVS driver i recognised so far is that it generates less voltage than its 555 counterpart ( hence smaller spark), but i can increase it with Villard cascade since it is a sine wave alternating current anyway. Furthermore, my pack of 1000 diodes had arrived yesterday from Hong Kong since bought it last week from ebay. So maybe i can use these diodes to create Villard cascade and some juice glass bottles for the high voltage capacitors.

Here is the schematic of the ZVS driver circuit, with the components are my own selection and the original circuit can be seen here.

About the circuit ( with reference to the schematic);

Speaking from experiences, I think the most critical parts of this circuit are the diodes, and the primary inductor. Prior to using 1N4007 diodes, i used 1N4148 and broke about 4 to 5 of them, maybe due to high current ( the high current split them into two!). Therefore, if u wanna choose suitable type of diodes, make sure their ratings can stand the current u wanna use. I also tested salvaged diodes from old TV, 1N5401 ( diodes for 3A current) and it works as well.

For the inductor, i just followed the recommended value by Mazilli which is between 40 to 200 microHenries. I chose 167microHenries, by winding breadboard wire with 35 turns around a ferrite core of 1cm diameter and 6cm length. Too low an inductance ( for example, lower than the recommended range) will cause overheating, while too high ( higher than the recommended range) will cause less voltage on the output.

Other parts are not quite critical, you may test by yourself, broken mosfets and diodes are common and something u always have to bear in mind when testing a power circuit like this.

Here are photos taken:

Overall setup

Flyback transformer. Notice 6 turns on each primary winding, both primary windings are connected to each other with a center tap.

Flyback transformer and the circuit ready for running

Power supply and inductor. Yellow thing is the inductor while the black wire is the laptop power supply that gives 9V, 3.16A power.

The most popular ZVS flyback driver nowadays amongst hobbyists is that designed by Vladimiro Mazilli. This driver is called zero voltage switching driver cuz it switches current exactly when the voltage across the MOSFET equals zero, and give a pure sine wave output, hence behaving like an DC-AC converter or 'inverter'. Due to its ability to convert the input DC into sine wave rather than sawtooth signal (from 555 driver circuit), hence the noise or the transformer's hum can be reduced or sometimes, entirely eliminated at all.

I ve been testing the ZVS driver with all electronic components i ve got so far ( since i dont wanna buy too much to reduce cost, i m short of money right now), and yesterday i finally found the most optimal configuration or variant of the circuit, where no more mosfet, diode and zener diode are broken ( honestly, i ve broke several zener diodes, some mosfets and also common rectifier diodes in the process).

The spark generated from the transformer is quite solid and smooth, no hum from the transformer's core, and the mosfet and all of the components on the circuit are not even getting warm at all. The only disadvantage from ZVS driver i recognised so far is that it generates less voltage than its 555 counterpart ( hence smaller spark), but i can increase it with Villard cascade since it is a sine wave alternating current anyway. Furthermore, my pack of 1000 diodes had arrived yesterday from Hong Kong since bought it last week from ebay. So maybe i can use these diodes to create Villard cascade and some juice glass bottles for the high voltage capacitors.

Here is the schematic of the ZVS driver circuit, with the components are my own selection and the original circuit can be seen here.

About the circuit ( with reference to the schematic);

Speaking from experiences, I think the most critical parts of this circuit are the diodes, and the primary inductor. Prior to using 1N4007 diodes, i used 1N4148 and broke about 4 to 5 of them, maybe due to high current ( the high current split them into two!). Therefore, if u wanna choose suitable type of diodes, make sure their ratings can stand the current u wanna use. I also tested salvaged diodes from old TV, 1N5401 ( diodes for 3A current) and it works as well.

For the inductor, i just followed the recommended value by Mazilli which is between 40 to 200 microHenries. I chose 167microHenries, by winding breadboard wire with 35 turns around a ferrite core of 1cm diameter and 6cm length. Too low an inductance ( for example, lower than the recommended range) will cause overheating, while too high ( higher than the recommended range) will cause less voltage on the output.

Other parts are not quite critical, you may test by yourself, broken mosfets and diodes are common and something u always have to bear in mind when testing a power circuit like this.

Here are photos taken:

Overall setup

Flyback transformer. Notice 6 turns on each primary winding, both primary windings are connected to each other with a center tap.

Flyback transformer and the circuit ready for running

Power supply and inductor. Yellow thing is the inductor while the black wire is the laptop power supply that gives 9V, 3.16A power.

Saturday, 23 July 2011

High voltage experiments: Part 3 - Homemade flyback transformer using ferrite rods

I am still lingering around flyback transformer and never start my tesla coil design since i am too absorbed and keen to know how does the flyback transformer work. For your information, before i got to have the ferrite c cores from the original flyback transformer from CRT tv, i have purchased four ferrite rods from Ebay as i ve planned to made them into my own handmade ferrite core or frame. As the rods were still in my room and i ve got nothing to do with it therefore i decided to resume to this plan, with a hope i will get useful knowledge on how the flyback transformer really works, and also a 'painful' experience in hand-winding the secondary coil of the transformer by myself!

By using the circuit in the previous post i ve tested my second handwound homemade flyback transformer, and surprisingly, it worked and as always, the beautiful blue/purple sparks appeared! I thought it would not working cuz i was just using ferrite rods which may be different from specially engineers-designed ferrite c cores for the original flyback transformer.

Before I move on, here is my current variant of the schematic. Please bear in mind that this circuit is designed by an amateur, so be careful with the high voltage output. This is not my final design and i am still improving it. I ve made my own Mazilli driver but it baked my MOSFETs ( due to minor mistake for not putting zener diodes)! So I retreat to this 555 driver but with separated power supplies cuz the circuit i ve been using before had damaged my 555 chip. Here is the schematic:

Please bear in mind that the value of the capacitances and resistances are not critical. You may change and experiment with other values depending on their suitability on your designed transformer. I m not an expert on this, so be careful cuz u are dealing with high voltage!

Without photos, there is no meaning. Therefore, i prefer speaking with photos accompanying me:

The overall setup. The flyback transformer i ve made with the ferrite rods frame is shown having yellow-taped secondary winding (larger winding) with red-taped primary winding (smaller winding), each wound around a ferrite rod, separated with two other ferrite rods on top ( visible) and at bottom ( invisible, located in the handmade box in white, near to the circular support from cellophan tape, under the transformer). Look at the following photo if u dont understand what ive meant:

Closer view on the circuit.

The flyback transformer. Note the spark gap on the pc cooling fan box.

Sparks were succesfully produced between the gap, but less powerful than those generated from original and homemade using C ferrite cores. I reckon that might be due to larger air gap within the core, and also might be due to saturated ferrite core.

Here are the photos explaining how the overall structure of the flyback transformer was made:

The complete assembly of my ferrite rods flyback transformer.

The top ferrite rod ( external diameter 1 cm, length 6cm, bought from Ebay) was removed from the structure to reveal the assembly. I used four similar rods to create the ferrite frame akin to that made of original double C ferrite cores in the original flyback transformer. Notice there are two other rods arranged vertically, wound with primary and secondary coils respectively. The last rod was embedded at the bottom of the structure, in the square base that will be explained later on.

The primary winding, wound on a similar ferrite rod, was taken apart. I just wound a common single core breadboard wire with about 12 turns, and then concealing the winding with the red PVC tape.

The secondary winding. I used similar method as before, except that i double the number of layer so it became larger and fitted the larger frame due to the dimensions of the rods. I also have changed the enamelled copper wire to smaller one ie 0.4mm external diameter. I dont know the exact number of layers and turns i ve made since its quite daunting to calculate it while u hand winding them. I just made it large enough so its distance from the primary coil is less than 1 cm. For this secondary i ve spent two days, each day i devoted about six hours of my life winding it, giving a total of 12 hours winding time. Thats approximately how much u will get if u produce it without special machines or toolings. I recommend u to make it to learn, since this thing cannot be learned by mere reading. U have to experience it in order to learn it.

The secondary is completely taken apart, revealing the white box that constitutes the base of the device and housing of the bottom horizontally configured ferrite rod.

Secondary winding, closer view on its leads. The yellow wire is carrying high voltage, while the smaller enamelled copper wire (0.4mm diameter) extended from the winding, is the high voltage earth.

Here are the photos of the square base:

The box is made from pizza's box. I cut it into shape desired to form the box that can house the ferrite rod and support two windings ferrite core vertically. The ferrite rod can be seen lying in the horizontal pit within the box. To make it u just simply need a cardboard (pizza box for convenience), tape, and scissors.

One main message that i want to convey thru this entry is that, if u have ferrite rods instead of ferrite C core, u can still make your own flyback transformer without need to spend money on buying such cores which are now becoming rare since most TVs now are using LCD screens. Therefore dont easily give up, just make it. And i have proven it to you that it works!

By using the circuit in the previous post i ve tested my second handwound homemade flyback transformer, and surprisingly, it worked and as always, the beautiful blue/purple sparks appeared! I thought it would not working cuz i was just using ferrite rods which may be different from specially engineers-designed ferrite c cores for the original flyback transformer.

Before I move on, here is my current variant of the schematic. Please bear in mind that this circuit is designed by an amateur, so be careful with the high voltage output. This is not my final design and i am still improving it. I ve made my own Mazilli driver but it baked my MOSFETs ( due to minor mistake for not putting zener diodes)! So I retreat to this 555 driver but with separated power supplies cuz the circuit i ve been using before had damaged my 555 chip. Here is the schematic:

Please bear in mind that the value of the capacitances and resistances are not critical. You may change and experiment with other values depending on their suitability on your designed transformer. I m not an expert on this, so be careful cuz u are dealing with high voltage!

Without photos, there is no meaning. Therefore, i prefer speaking with photos accompanying me:

The overall setup. The flyback transformer i ve made with the ferrite rods frame is shown having yellow-taped secondary winding (larger winding) with red-taped primary winding (smaller winding), each wound around a ferrite rod, separated with two other ferrite rods on top ( visible) and at bottom ( invisible, located in the handmade box in white, near to the circular support from cellophan tape, under the transformer). Look at the following photo if u dont understand what ive meant:

Closer view on the circuit.

The flyback transformer. Note the spark gap on the pc cooling fan box.

Sparks were succesfully produced between the gap, but less powerful than those generated from original and homemade using C ferrite cores. I reckon that might be due to larger air gap within the core, and also might be due to saturated ferrite core.

Here are the photos explaining how the overall structure of the flyback transformer was made:

The complete assembly of my ferrite rods flyback transformer.

The top ferrite rod ( external diameter 1 cm, length 6cm, bought from Ebay) was removed from the structure to reveal the assembly. I used four similar rods to create the ferrite frame akin to that made of original double C ferrite cores in the original flyback transformer. Notice there are two other rods arranged vertically, wound with primary and secondary coils respectively. The last rod was embedded at the bottom of the structure, in the square base that will be explained later on.

The primary winding, wound on a similar ferrite rod, was taken apart. I just wound a common single core breadboard wire with about 12 turns, and then concealing the winding with the red PVC tape.

The secondary winding. I used similar method as before, except that i double the number of layer so it became larger and fitted the larger frame due to the dimensions of the rods. I also have changed the enamelled copper wire to smaller one ie 0.4mm external diameter. I dont know the exact number of layers and turns i ve made since its quite daunting to calculate it while u hand winding them. I just made it large enough so its distance from the primary coil is less than 1 cm. For this secondary i ve spent two days, each day i devoted about six hours of my life winding it, giving a total of 12 hours winding time. Thats approximately how much u will get if u produce it without special machines or toolings. I recommend u to make it to learn, since this thing cannot be learned by mere reading. U have to experience it in order to learn it.

The secondary is completely taken apart, revealing the white box that constitutes the base of the device and housing of the bottom horizontally configured ferrite rod.

Secondary winding, closer view on its leads. The yellow wire is carrying high voltage, while the smaller enamelled copper wire (0.4mm diameter) extended from the winding, is the high voltage earth.

Here are the photos of the square base:

The box is made from pizza's box. I cut it into shape desired to form the box that can house the ferrite rod and support two windings ferrite core vertically. The ferrite rod can be seen lying in the horizontal pit within the box. To make it u just simply need a cardboard (pizza box for convenience), tape, and scissors.

One main message that i want to convey thru this entry is that, if u have ferrite rods instead of ferrite C core, u can still make your own flyback transformer without need to spend money on buying such cores which are now becoming rare since most TVs now are using LCD screens. Therefore dont easily give up, just make it. And i have proven it to you that it works!

Subscribe to:

Posts (Atom)

click for larger version

click for larger version